Being Cool isn’t always a good thing!

We, as homeowners, seem to always want our homes to look amazing. From the paint

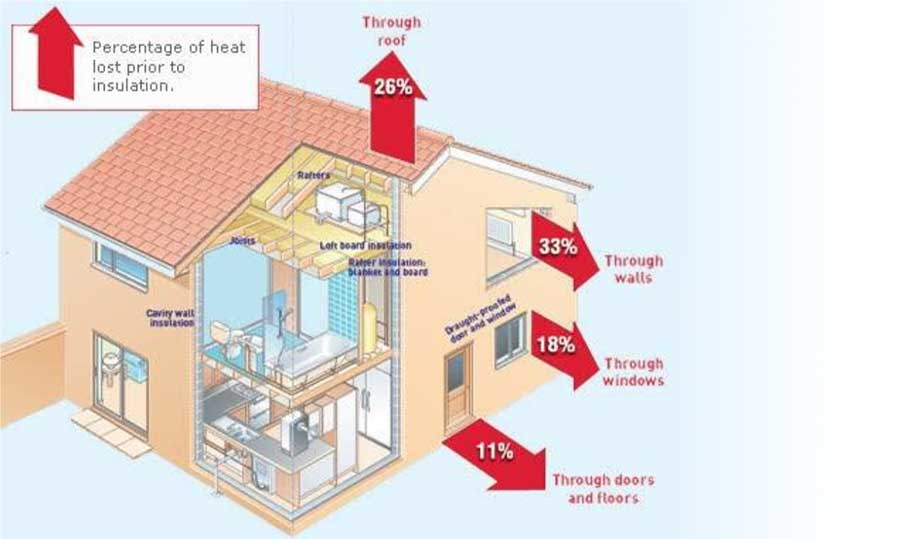

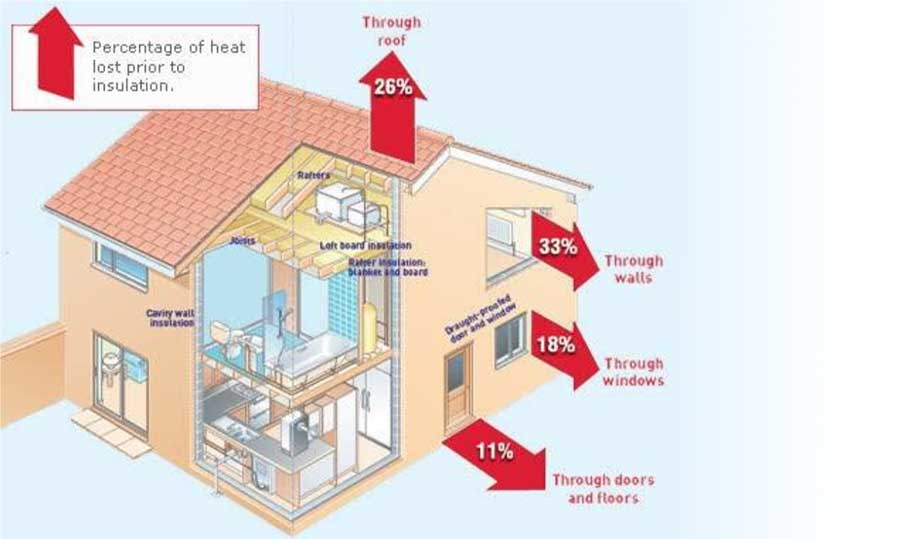

Read MoreIncreasing the insulation, and replacing old doors and windows is going to save energy and as a result your home will be considered more green.

Some insulations are definitely greener than others. There are tremendous differences between cellulose and fiberglass. Individual homeowners can make a significant environmental impact by choosing the most environmentally responsible, highest performance insulation for just one home. Builders, architects, and insulation contractors who influence the choice of insulation for many buildings also have the opportunity to make a profound impact.

At INTEC, we encourage our clients to take into consideration the green factor when choosing the insulation for their project.

Studies have shown that increasing your home insulation saves energy every year. However, if one type of insulation is more effective than another, it can help save even more energy, and money. Studies at universities, national laboratories, private research facilities and hundreds of homes and buildings have shown that cellulose is from 20% to 50% more effective than fiberglass.

Insulation can be an excellent, high-quality end use for materials that would otherwise be dumped into landfills. Cellulose and fiberglass insulation have recycled contents varying from 9% to 85%. Cellulose contains from 75% to 85% post-consumer recycled newsprint. Fiberglass products contain from 0% to 35% pre-consumer recycled glass.

The amount of energy consumed to manufacture a product known as its “embodied energy.” Cellulose insulation is manufactured in fairly small plants which process recycled newsprint. This equipment is powered by relatively small electric motors.

Fiberglass is manufactured in large blast ovens which consume vast amounts of natural gas to melt sand and chemical additives into glass. The necessary equipment is enormous in size, complexity, and in its appetite for energy. Manufacturing fiberglass for a home consumes six times more energy than manufacturing cellulose to insulate the same house to the same R-Value.

Standing outside a cellulose plant, one can hear humming motors, but there are no smoke plumes and no odors because there are virtually zero emissions.

Manufacturing fiberglass generates glass dust and huge quantities of carbon dioxide from natural gas fired blast furnaces (manufacturing fiberglass insulation for just one home generates over 1,200 pounds of carbon dioxide). Fiberglass plants also generate enormous amounts of other chemicals used in its manufacture (formaldehyde, urea, polyvinyl acetate, chlorides, etc.)

We, as homeowners, seem to always want our homes to look amazing. From the paint

Read More

Winter’s coming. It’s already heating season. So how do you save money on he

Read More

Do you know the truth about what does and does not save energy? These days, many

Read More